When materials need to be broken down, manufacturers use mixers. A mixer can be any machine that can blend, homogenize, or emulsify a various type of materials into a single substance. Mixers—also known as blenders—are capable of thoroughly combining any liquid or solid that a final product requires. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

Ross is a manufacturer of industrial mixing, blending and dispersion equipment since 1842. We offer sanitary, standard and custom equipment designed to meet the varied mixing requirements of our customers from virtually all the process industries. Our plants in the United States, China and India are all fully equipped with advanced engineering and production tools. In the US alone, we operate ...

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

For more than 75 years, we have provided custom designed industrial mixing, drying, moving and controlling solutions for the food, plastics, minerals, chemicals, and biomass industries, manufactured to fit the specific requirements of one type of application- yours. It’s simple really, when you’re proud of your work, you sign your name to it. You’ll find it on everything we build. After...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More Industrial Mixer Manufacturers

Mixer Applications

Mixers play a vital role across various industries, serving as essential machinery for the initial stages of production. They are ubiquitous in sectors ranging from adhesive and sealant manufacturing to water treatment, automotive, pulp and paper production, agriculture, chemicals, pharmaceuticals, food and beverage, and cosmetics. These versatile tools are extensively employed to thoroughly blend and break down materials.

Typically utilized during processing and manufacturing, mixers leverage their robust motorized blades to amalgamate a diverse array of substances. They facilitate the creation of products like polyurethane, silicone, petroleum derivatives, toothpaste, hair care items, detergents, shampoos, vitamins, lotions, creams, ointments, milk, syrups, medications, dry and liquid chemicals, biodiesel, and cement.

History of Industrial Mixers

Since the mid to late 1800s, modern mixers have revolutionized kitchen dynamics. Originating in Baltimore, Maryland, the first patented mixer in 1856 was initially tailored for domestic use, swiftly proving its utility to users. This breakthrough sparked a flurry of innovations in mixer and mixer bowl designs by manufacturers.

By 1885, Rufus Eastman ushered in a new era with the invention of the first electric motor mixer. Harnessing electricity significantly enhanced mixer efficiency and power, marking a pivotal advancement in culinary technology.

In a pivotal moment at the brink of the 20th century, engineers at the Hobart Manufacturing Company pioneered a breakthrough: the industrial-sized mixer. Among their pioneering creations was the standing mixer, conceptualized in 1908 by Herbert Johnson. Inspired by a baker’s manual stirring with a metal spoon, Johnson sought to automate this process, propelling the company’s ascent. By 1915, their 20-gallon standing mixer had become a staple in bakeries nationwide, marking a significant milestone in culinary technology.

Following this innovation, manufacturers adopted mixers for blending various bulk powders. Since then, the versatility of mixers has expanded dramatically across numerous industries. Nowadays, mixers play pivotal roles in an extensive array of applications, spanning household, heavy-duty industrial, and laboratory settings alike.

Types of Industrial Mixers

Paddle Mixer

A paddle mixer, characterized by its large paddles revolving around a horizontal axis, represents one variety of mixers.

Static Mixer

A different kind of mixer, known as a static mixer, employs flat, thin blades shaped like ribbons. These mixers are distinguished by their lack of moving parts. Instead of traditional blades, they feature strategically placed obstructions that vigorously combine materials. Static mixers are prized for their sanitary design and ease of maintenance, facilitated by the straightforward configuration of their blades.

High Shear Mixer

High shear mixers, unlike their static counterparts, spin into action at high velocities, purpose-built for tasks like emulsifying, breaking down particles, dispersing, and homogenizing a wide array of solids and liquids. They excel particularly in sectors such as food preparation, paper and pulp, and pharmaceuticals.

Drum Mixer

Drum mixers are specialized devices designed to blend materials with low to medium viscosity, such as adhesives or cement. Constructed from gallon drums that rotate, these mixers effectively combine materials of diverse particle sizes. Typically, they handle a range of substances from slurries to other low to medium viscosity materials.

Food Mixer

Certain blendings are employed to impart a distinct effect or visual appeal to the end result when combined with specific substances. Take food mixers, for instance. They’re widely utilized to whip, knead, blend, fold, mix, or beat edible components. Due to rigorous food and health standards, it’s crucial that these mixers maintain strict sanitary conditions.

Blender

While often used interchangeably with “mixer,” the term blender specifically denotes a device with sharp blades designed to operate at high speeds. Blenders excel at reducing materials into smaller pieces.

Planetary Mixer

Planetary mixers, celestial agitators of the kitchen and laboratory alike, twirl around mixing bowls in a graceful orbit, stirring dough in kitchens and blending chemicals in labs. Their name derives from their celestial-like motion, tracing elliptical or circular paths along the edges of their bowls.

Homogenizer

Homogenizers serve to thoroughly blend and disintegrate materials. Over the years, industries spanning science, technology, and food processing have relied on these devices. Everyday consumables like milk and cream are prime instances of products benefiting from homogenization processes.

Emulsifier

Emulsifiers are powerful mixers equipped with a perforated screen, enabling them to seamlessly blend materials that would otherwise be extremely challenging to combine.

Agitator

Agitators are employed to handle low-viscosity substances like liquids. This agitation primarily serves as an auxiliary step, supporting the main process. It’s important to note that agitators are less effective with thicker, more viscous materials.

Batch Mixer

Batch mixers are primarily employed to combine materials that require different mixing durations. In this process, the mixers handle one batch of material at a time, blending it thoroughly before being reloaded with the next batch.

Ribbon Mixer

Ribbon mixers operate without any moving parts, relying on their flat, thin blades to act as stationary barriers. As materials flow around these blades, they naturally mix and blend. This static mixing process ensures thorough integration of the components. Additionally, ribbon mixers, like other static mixers, are designed for easy cleaning.

Ribbon Blenders

Ribbon blenders are adaptable and easily scalable mixing machines. Industries such as pharmaceuticals, agriculture, chemicals, and food processing rely on ribbon blenders to blend powders, granules, pellets, flakes, and other dry solids. A well-designed ribbon blender, with precisely controlled clearance between its surfaces and the helical agitator tips, ensures swift and uniform mixing of powders.

- Considerations in Selecting a Ribbon Blender

- When selecting a ribbon blender, it’s crucial to consider the specific process it will serve. The right choice can significantly impact the speed and efficiency of your mixing tasks. Here are some key factors to keep in mind:

- Size and Volume of Ribbon Blenders

- When choosing a ribbon blender, it’s crucial to focus on volume and profile, which hinge on the quantity of material and mixing speed. Depending on your needs, a larger blender might be ideal, or you might opt for several smaller ones to boost production efficiency.

- Ribbon Type

- Ribbon mixers combine ingredients using helical metal blades that create a dynamic blending action. The outer helix, or external ribbon, pushes the material inward, while the inner helix drives it outward, ensuring thorough circulation. This method offers a gentle yet rapid mixing process. For certain materials, such as solid pastes and high-liquid ingredients, thicker paddles may be more effective than thin ribbons, optimizing the mixing performance for these specific textures.

- Correct Horsepower

- Choosing the right horsepower for your ribbon blender is crucial for achieving optimal mixing efficiency. Overpowering the blender can lead to unnecessary expenses, while insufficient power may prevent the mixer from starting or operating correctly.

- Ribbon Blender Construction Materials

- The choice of construction materials for ribbon blenders hinges on the characteristics of the ingredients to be mixed and their intended applications. For food processing and pharmaceutical purposes, mixers should be crafted from stainless steel with a premium finish, ensuring they can be easily cleaned and sanitized.

- Discharge Method in the Mixer

- The method of releasing ingredients plays a vital role in selecting the appropriate ribbon mixer. Various mixing processes demand distinct discharge techniques. Some materials necessitate a swift and immediate release for proper handling; in such instances, drop bottom discharge gates are perfect. Conversely, other materials require a gradual pour instead of an abrupt release; ribbon mixers equipped with slide gates are more suitable for these situations.

- Conclusion

- Ribbon mixers are invaluable assets across numerous industries, such as food processing and pharmaceuticals. Alongside other technologies like tablet coating machines, tablet counters, cartoning machines, and blister packaging machines, these mixers contribute significantly to enhancing convenience and comfort, particularly in medicine and nutrition.

- Selecting the appropriate ribbon blender for your manufacturing process can streamline and optimize your production line while ensuring product quality. By considering the properties of the materials you will use and how a ribbon blender can meet your needs, you can prevent potential issues and concerns down the line.

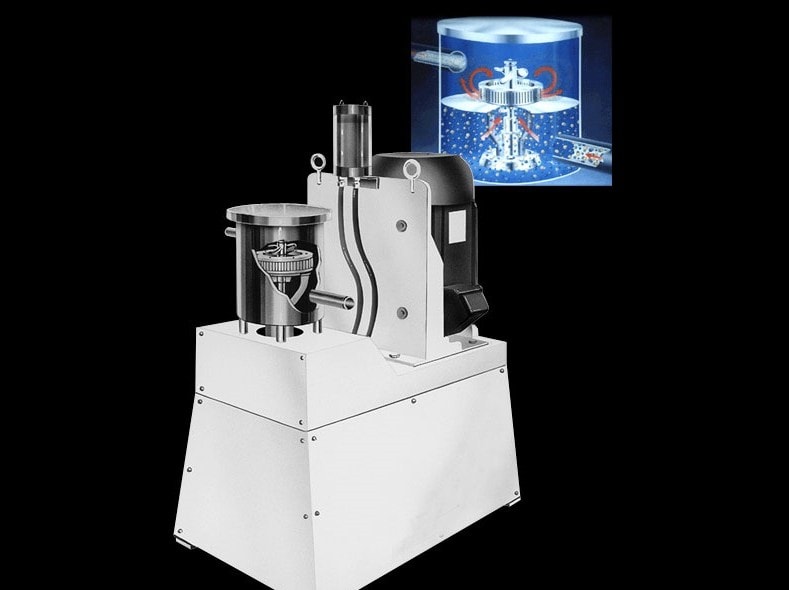

Industrial Mixer

Industrial mixers feature a spacious vat or tank designed to contain materials, equipped with powerful blades that vigorously stir and blend the contents. Industries engaged in large-scale commercial production typically rely on these mixers, as they are adept at handling and processing substantial volumes of materials efficiently.

In-Line Mixer

In-line mixers, positioned within pipelines and integrated with material flows, offer a unique approach to mixing. Instead of blending materials in a traditional tank, they perform the task directly within the pipe. This innovative method enables the processing of remarkably large batches with minimal horsepower. Additionally, they ensure consistent batch turnover.

There are two primary types of in-line mixers: static and dynamic. Static in-line mixers rely on fixed, contoured components to achieve mixing, while dynamic in-line mixers utilize a blend of high-speed rotating elements and pump pressure to accomplish the same.

Stand Mixer

Stand mixers, also referred to as standing mixers, are designed to sit atop their motors, allowing them to remain upright. These versatile appliances come in a wide range of sizes, from compact 1-gallon countertop models to large commercial versions that can hold up to 25 gallons.

Portable Mixer

Portable mixers are versatile tools designed to bring essential mixing and blending capabilities directly to where they’re needed most, eliminating the inconvenience of off-site operations. Contractors, for instance, rely on portable cement mixers for tasks such as driveway concrete mixing. These mixers can be easily transported, either mounted on trucks or trailers for in-transit use or independently maneuvered and powered by electricity.

Tank Mixer

Tank mixers, also known as mixer tanks, are machines designed to mix materials using stainless steel tanks.

Mixer Equipment Components

The typical components of a mixer include a primary chamber, typically a sizable vat or tank, and a motorized assembly of paddles or blades that spin around an axis.

Depending on its intended use, the mixer may be equipped with either flat paddles or sharp blades. These attachments are often designed to be removable, allowing the mixer to accommodate a diverse range of materials.

Benefits of Industrial Mixers

Mixer systems provide users with a host of advantages: consistency, efficiency, user-friendliness, and durability. While mixing materials manually remains an option, mixers deliver a level of output consistency that’s unmatched. Moreover, alternative methods struggle to blend materials as thoroughly and swiftly. Designed for optimal performance and longevity, mixers ensure your products are uniformly mixed and reliably produced over the long term.

Mixer Design and Customization

Materials

Typically crafted from stainless steel for its sanitary and corrosion-resistant properties, mixers can also be constructed from aluminum, cast iron, steel, titanium, or thermoplastic.

Considerations

When designing a mixer, manufacturers face critical decisions concerning materials, blade type, design, and motor power. These choices hinge on specific application requirements such as material viscosity, volume, corrosiveness, available space, and sanitation standards.

Manufacturers strive for meticulous assembly using durable, corrosion-resistant materials with smooth surfaces, as previously discussed. Their ultimate aim is to ensure longevity and optimal performance.

Customization

Customization of mixing equipment by manufacturers is not particularly widespread, yet it presents notable benefits that merit attention. Custom-built mixers, tailored for specific needs, provide operators enhanced control over the mixing process, leading to more precise outcomes. Additionally, these specialized machines tend to exhibit slower wear and tear compared to their standard counterparts, thanks to their bespoke design. Common enhancements in these mixers include the capability to blend diverse materials at high velocities and adaptations that allow the machinery to manage significant pressure variations effectively.

Safety and Compliance Standards

When choosing a mixer, prioritize reliability and robust durability. We advise selecting only those mixers that bear the seal of approval from respected and universally recognized standards organizations. In the United States, a prime example is the American Society of Mechanical Engineers (ASME).

Your specific field, industry, and geographical location might necessitate additional standards. Commonly referenced ones include API, UL, USFDA, BISC, and ABS. For further insights, consider engaging with industry experts and relevant government agencies.

Choosing the Right Mixer Manufacturer

While it’s temptingly convenient to snag standard processing gear with a few clicks online, truly valuing your business means choosing to collaborate with a seasoned mixer supplier. This doesn’t negate the importance of a digital perusal of their offerings; rather, it transcends merely scanning product descriptions and impulsively hitting “add to cart.” For optimal results, engage in a dialogue with a specialist who can ensure the equipment suits your specific needs and tweak it if necessary. Start your search with the mixer manufacturers highlighted on this page. Each supplier listed has consistently demonstrated their commitment to excellence and customer satisfaction, earning them a reputation for quality work and stellar service.

To select the best manufacturer from the options available, start by creating a detailed list of specifications. Review the manufacturers listed and keep referring to your list as you browse to stay focused. Identify three or four manufacturers who seem most capable of meeting your needs and contact them for quotes. Make sure to discuss your requirements, budget, timeline, and delivery preferences with each. After speaking with each manufacturer, compare their responses carefully. Finally, choose the one that best meets your criteria.

Check out our Bulk Material Handling Equipment website

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services