The term “agitator” refers to a device that uses a revolving impeller and shaft to impart mechanical energy to shake or agitate a liquid or combination of liquids. The chemical, pharmaceutical, food, grease, metal extraction, paint, adhesive, water, and cosmetic sectors employ agitators extensively for various tasks. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

Ross is a manufacturer of industrial mixing, blending and dispersion equipment since 1842. We offer sanitary, standard and custom equipment designed to meet the varied mixing requirements of our customers from virtually all the process industries. Our plants in the United States, China and India are all fully equipped with advanced engineering and production tools. In the US alone, we operate ...

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

For more than 75 years, we have provided custom designed industrial mixing, drying, moving and controlling solutions for the food, plastics, minerals, chemicals, and biomass industries, manufactured to fit the specific requirements of one type of application- yours. It’s simple really, when you’re proud of your work, you sign your name to it. You’ll find it on everything we build. After...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More Agitator Manufacturers

Uses Of Agitators

An agitator is mostly used in plants for the following reasons:

- To ensure appropriate liquid mixing

- To encourage chemical reactions within the apparatus

- To boost heat transfer when cooling or heating

- To maintain uniform liquid bulk while being stored

- To spread immiscible liquids about

- To maintain the mixture of the product until it is used

- To form miscible solutions

- To cause some solids to dissolve in a liquid

Types of Agitators

Agitators come in a variety of types, some appropriate for industrial use. There are several common types of agitators:

- Paddle agitators

- Anchor type agitators

- Propeller type agitators

- Blade type agitators

- Turbine type agitators

- Helical agitators

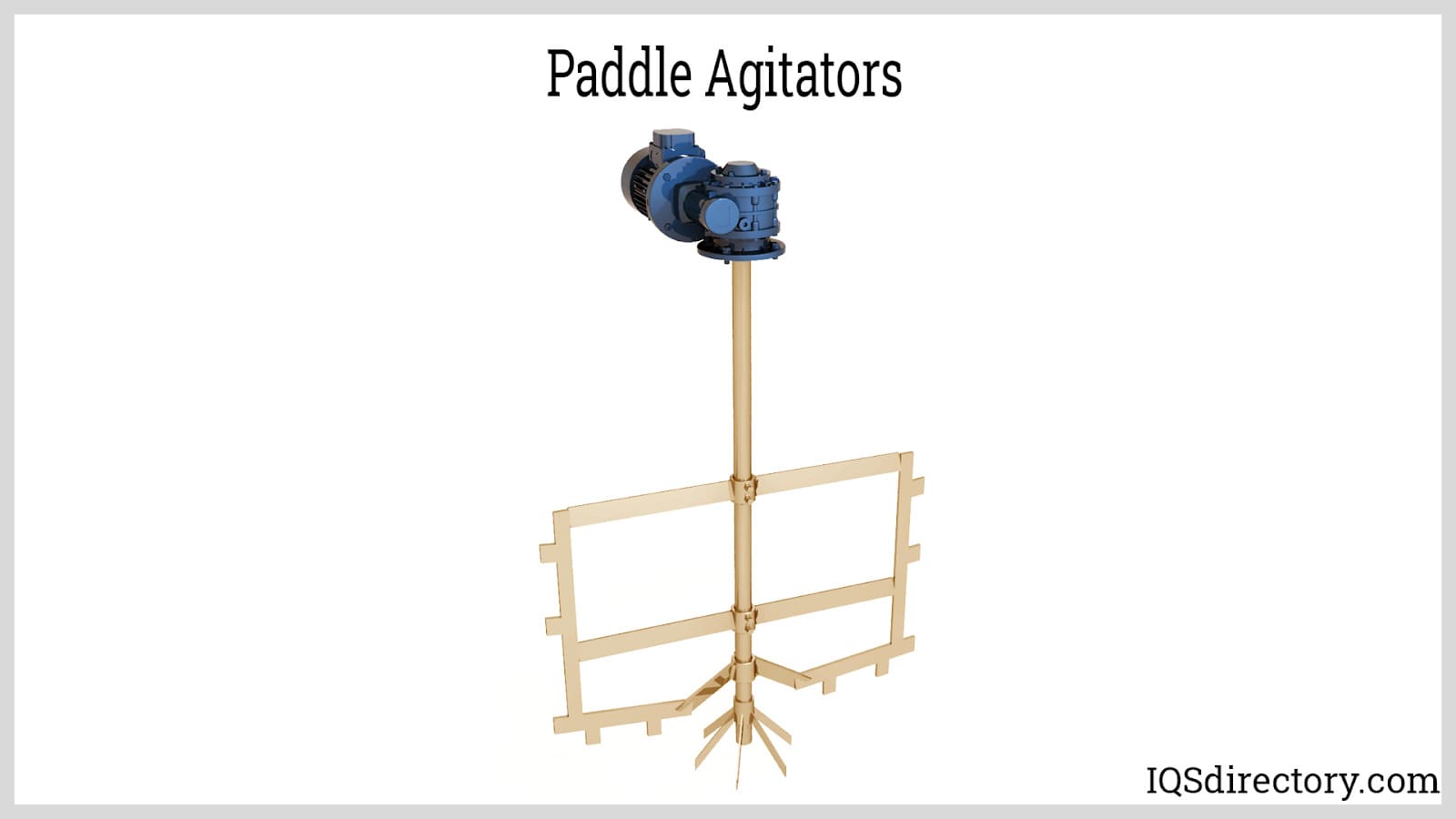

Paddle Agitators

Paddle agitators have paddle-shaped blades, the most fundamental kind. Due to their restricted capabilities, they are utilized primarily for laminar flow fluids with minimal shearing requirements. They can transport ingredients from one end of the vessel to the other and have an equal number of forward and reverse paddles.

Applications of Paddle Agitators

- Combining solids

- Mixing slurry during the crystallization step of the supersaturated cooling process

Advantages of Paddle Agitators

- Paddle agitators can be used for heavy-duty applications, including slurry mixing and slow operation.

- Two to four blades make these agitators more effective.

Disadvantages of Paddle Agitators

- These agitators consumes much electrical energy.

- They are ineffective at blending.

Sawtooth Paddle Agitators are a modified form of paddle agitators. These agitators have saw teeth or notches in their front puddles.

Other Agitators

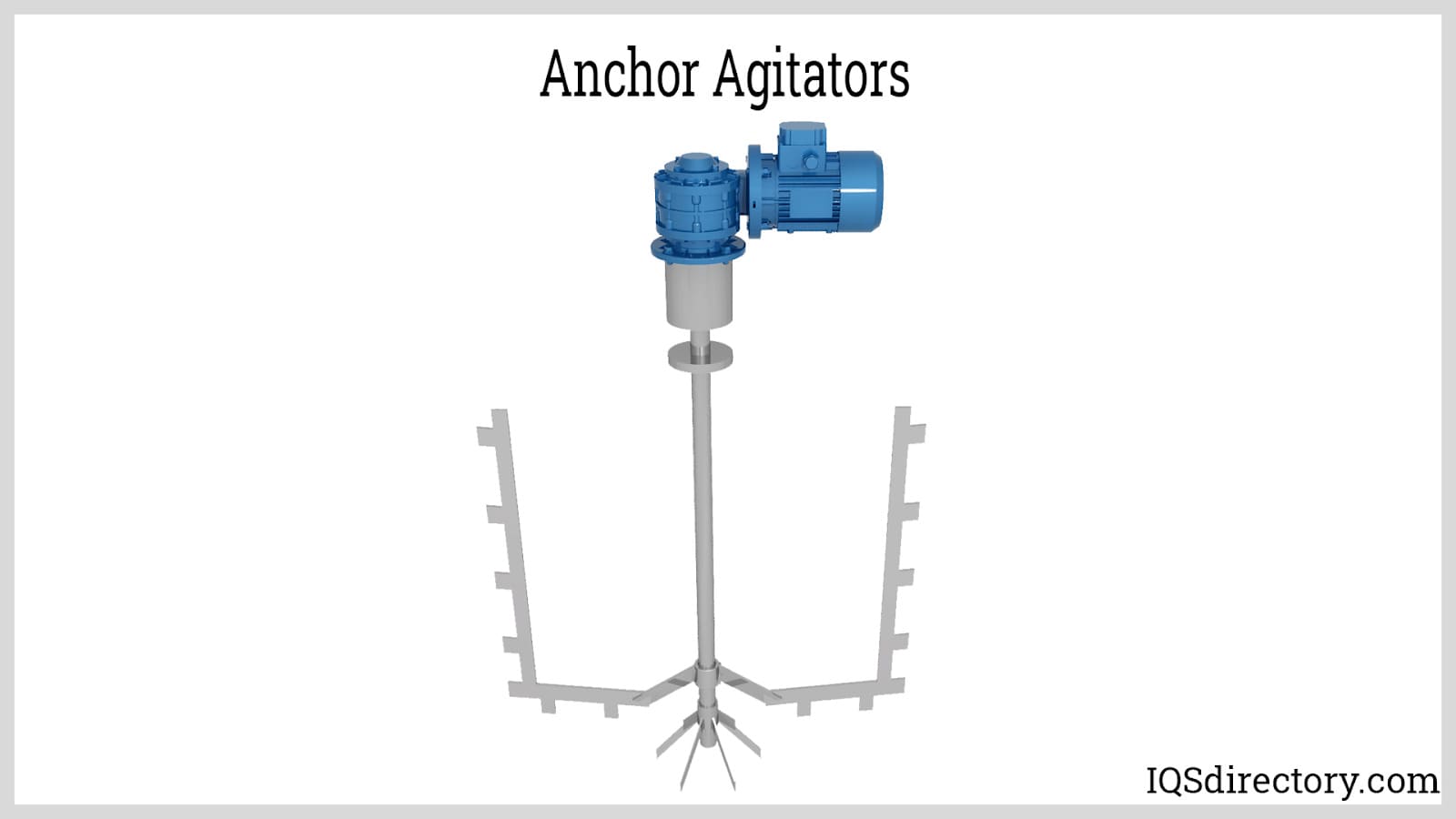

Anchor Agitators: Anchor agitators are frequently employed to mix non-Newtonian and highly viscous fluids. Their name refers to the impeller's shape, similar to an anchor. Typically, they are installed in tanks and other vessels with rounded or conical bottoms. The pharmaceutical industry makes extensive use of anchor agitators. Anchor agitators have the benefit of allowing for high heat transfer rates.

Propeller Agitators: Propeller agitators are excellent choices for materials with low viscosities. Propeller-type agitators running at medium to high speeds make it simple to accomplish tasks like homogenization, suspension, and dispersion. These axial flow agitators are perfect for solid-in-liquid suspensions because they stop solid particles from depositing. In addition, propeller agitators have the benefit of being able to dry and press materials while also handling corrosive materials with a glass lining. However, using propeller agitators has the drawback of requiring high speed, which will cost more money for electric motors.

Blade Type Agitators: These are appropriate for fluids with low and medium viscosities. Axial-type agitators have blades.

Turbine Agitators: They are employed for the rapid emulsification and dispersion of fluids. Many liquids, gas reactions, and extraction processes use turbine agitators. Turbine agitators have excellent mixing performance over different kinds of viscosities. An axial input and a radial output are features of turbine agitators. While working, they combine rotation and centrifugal force. As a result, turbine agitators benefit from strong radial flow, which is beneficial for dispersion operation.

Helical Agitators: They are called helical agitators because the blades are arranged in a helix-like pattern. Helical agitators are axial flow agitators that produce violent motion inside the vessel or tank and appear like threaded screws. This agitator is popular in the paint and polymer industries since it can effectively handle liquids with viscoelasticity.

Components of an Agitator

An agitator typically consists of these three elements:

- A shaft with an impeller and blades for the impeller

- A motor with the possibility of a gearbox

- A mechanical seal

The impeller of the agitator rotates to perform mixing because its shaft is attached to the motor and gearbox. The volume of liquid inside the tank or vessel determines how many impellers are needed. Typically, each impeller has 2 to 6 blades. Magnetic-driven agitators are also an option in cases where a hermetic seal is employed in place of a mechanical seal.

Different types of impellers can be used in agitators, including:

- Standard or wide blade hydrofoils

- Straight blade or pitched blade turbines

- Retreat curved impellers

- Gas dispersion impellers

- Rushton turbine impellers

- Sawtooth disk impellers

Selection Criteria of Industrial Agitators

The choice of agitators for a given application depends on several variables, including:

- The mixture phase (single-phase or multiphase)

- The bulk's viscosity

- The precise function needed (blending, dissolving, dispersion, heat exchange, chemical reaction, crystallization, emulsification, suspension, etc.)

- The cycle of mixing (batch size, the time required for agitation, material addition sequence, etc.)

- characteristics of the components to be combined

- Viscosities of the initial ingredients and the end product

- Solids' solubility and the used concentration

- Desired results of the process

- Corrosive or explosive qualities

Calculation procedures for the number of Agitators

The shaft may be attached to more than one agitator. The equation below can be used to determine the number of agitators and the distance between two agitators:

Number of Agitators = (Maximum liquid height X Specific gravity)/Diameter of the Vessel.

The gap between two Agitators=Liquid Height/(Number of Impellers-0.5).

Choosing the Right Agitator Supplier

To ensure you have the most beneficial outcome when purchasing agitators from an agitator supplier, it is important to compare several companies using our directory of agitator suppliers. Each agitator supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each agitator business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple agitator companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services