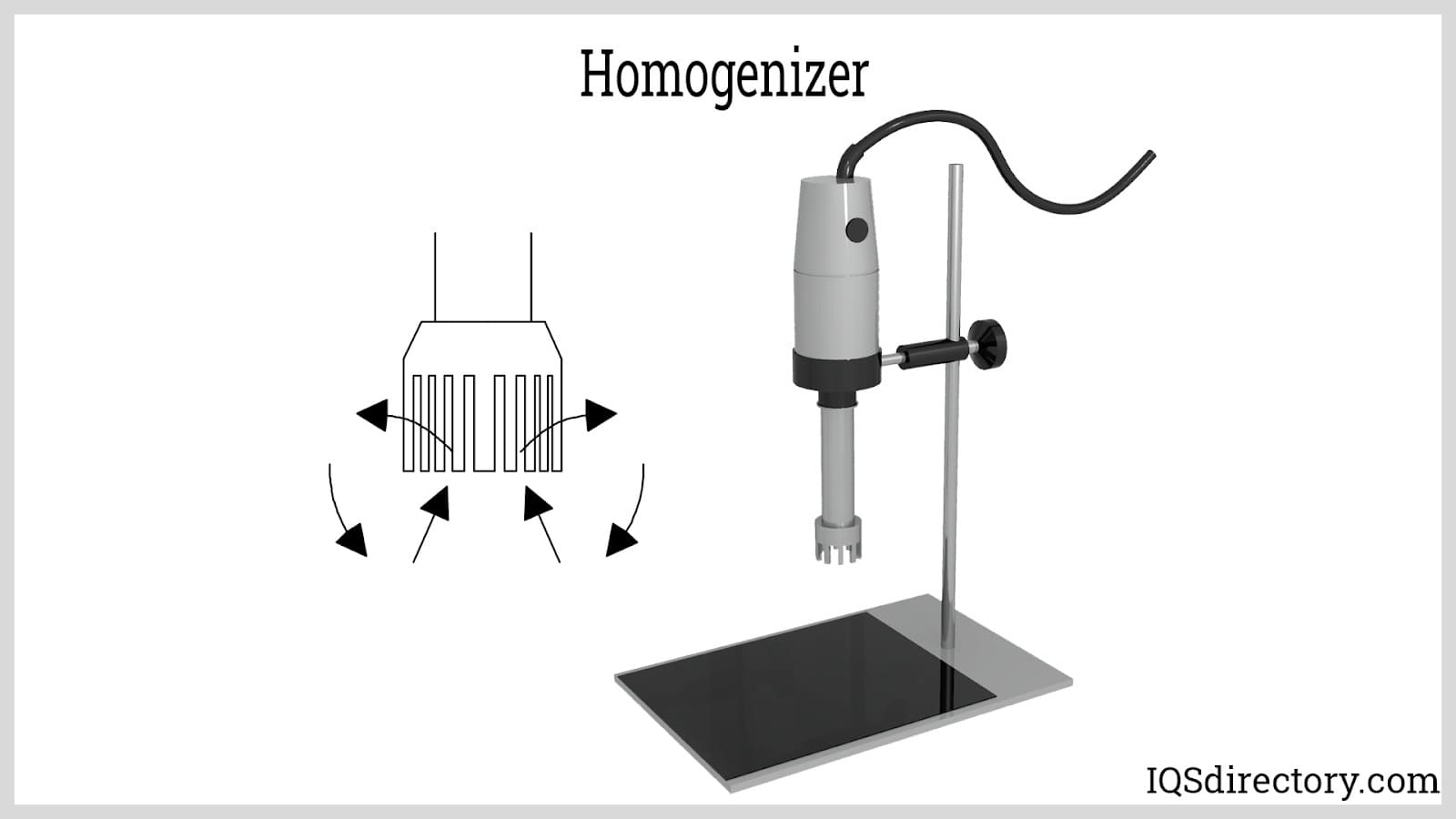

A homogenizer is a piece of industrial equipment used to homogenize various materials such as soil, tissue, plants, food, and more. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

Ross manufactures the world’s broadest line of High Shear Mixers – from traditional High Speed Dispersers and single-stage Rotor/Stator Mixers to new generation ultra- high shear patented mixing technologies. Our high performance rotor/stator mixers, also sometimes called homogenizers, are available in sizes from benchtop through full-scale production, in batch and in-line configurations, ...

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

For more than 75 years, we have provided custom designed industrial mixing, drying, moving and controlling solutions for the food, plastics, minerals, chemicals, and biomass industries, manufactured to fit the specific requirements of one type of application- yours. It’s simple really, when you’re proud of your work, you sign your name to it. You’ll find it on everything we build. After...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More Homogenizer Manufacturers

Types of Homogenizers

- Rotor-stator

- Ultrasonic

- Bead mill

- High-pressure

- Paddle blender

- Mortar and pestle

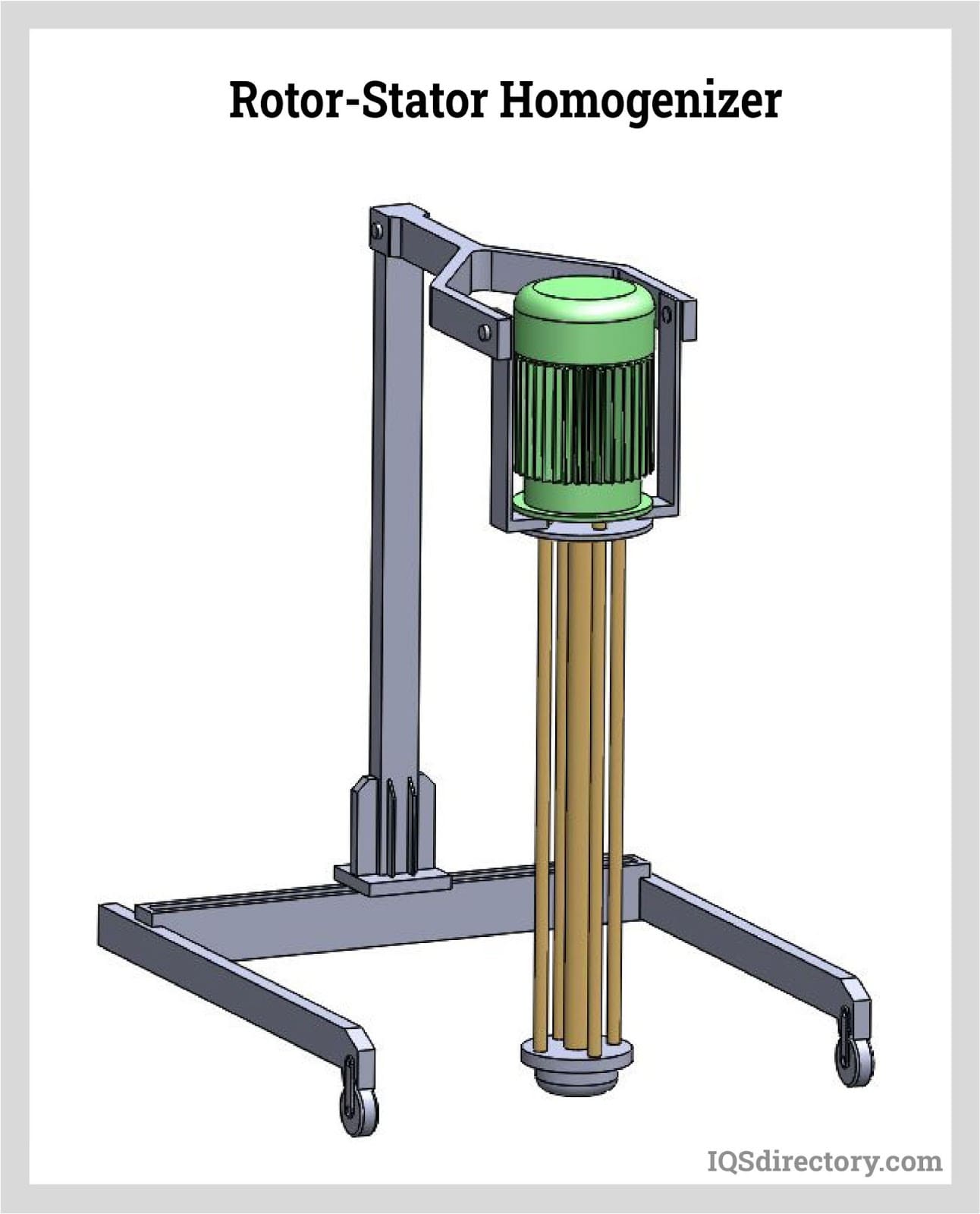

Rotor-Stator Homogenization

A metal shaft (rotor) that rotates quickly inside a stationary exterior container (stator) makes up a Rotor-stator homogenizer. The suction effect created the rotation draws the sample into the space between the two components. Here, it is exposed to extremely strong shear forces that aid in blending the liquid or particles. A continuous process is created as the sample is forced through slots in the stator. As a result, more sample enters the area to be sheared due to the fluid's rapid velocity.

Uses

These homogenizers can be used for mixing or emulsifying liquids and suspensions in various applications. They can also be used to homogenize soft tissue and lyse cells.

Benefits

A wide volume range can be covered thanks to the option to change probes. For single samples, this method offers a quick and effective solution.

Drawbacks

- Rotor-stator homogenizers are not appropriate for multi-sample high-throughput applications due to the use of probes.

- Since rotor-stator homogenizers generate heat, it is necessary to chill heat-sensitive samples.

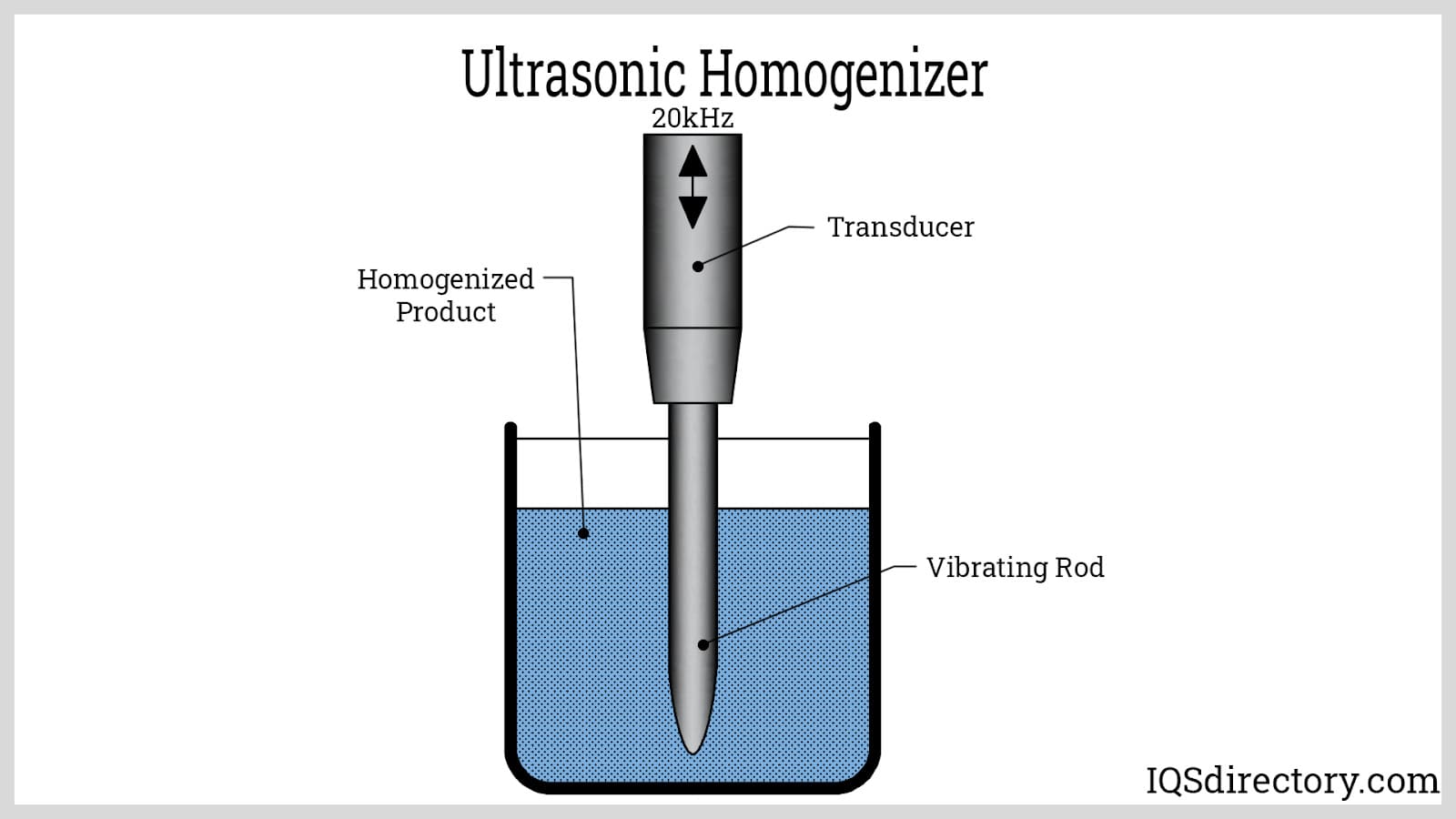

Ultrasonic Homogenization

Sonicators, another name for ultrasonic homogenizers, also employ a probe (horn). Rapid probe vibrations cause the surrounding sample to receive ultrasonic energy. Additionally, cavitation, the fast creation and collapse of bubbles, is a byproduct of the sonication process. Shock waves are produced as a result, homogenizing the surrounding sample. Small particle sizes can be achieved with ultrasonic homogenizers in comparatively little time. However, ear protection should be used because these homogenizers produce a lot of noise.

Uses

DNA shearing, cell or tissue destruction, and particle size reduction are typical applications for ultrasonic homogenizers. However, this apparatus cannot be used with dry samples because it is made for liquid samples only.

Benefits

- They can distribute a lot of energy over a little space.

- They can produce tiny particles in a short amount of time.

Drawbacks

- For some applications, the possibility of trace levels of titanium appearing in the sample as a result of the treatment can be of concern.

- Ultrasonic homogenizers might not be appropriate for applications that require a low temperature because they can produce much heat.

Bead Mill Homogenization

A bead mill homogenizer uses beads, as the name would imply. The sample and beads are put in a tube and forcefully shaken. The sample gets homogenized due to the beads' motion and collisions with one another. For different machines, the agitation of the beads is accomplished through a violent shaking motion.

Uses

This application is appropriate for high-throughput applications since it can homogenize several samples simultaneously. Cell disruption and tissue tearing up are a few examples of usage. In addition, bead mills can be used to grind or mill solids since they can be utilized with dry samples.

Benefits

- Since disposable tubes are used, there is almost no possibility of infection.

- The possibility of aerosolization is reduced because the tubes are closed.

- The availability of numerous types of beads for different purposes increases the range of possible applications.

Drawbacks

- Laboratory-scale bead mill homogenization is only appropriate for tiny samples due to the nature of the procedure. For example, only process a few grams or milliliters in a single tube.

- Minute amounts of the bead material may end up in a sample, which could be problematic for some applications.

High-Pressure Homogenization

High-pressure homogenization homogenizes liquid samples at high pressure by subjecting the sample to a powerful force. In a typical arrangement, the sample is forced inside via a channel, such as a valve or tiny slits in a membrane. The ensuing shear, pressure decrease, and cavitation will homogenize the sample. Sometimes, the high-pressure stream colliding with a blade, plate, or ring helps homogenize the mixture.

Uses

Large quantities that need to be homogenized are frequently subjected to high-pressure homogenization. However, many models support recyclability, and when combined with aggressive processing, it is possible to achieve very small particle sizes.

Benefits

Some high-pressure homogenizers are highly flexible and can be used for various purposes.

Drawbacks

These devices may have a significant price tag and are huge and heavy.

Paddle Blender Homogenization

Unlike the other items on the list, a paddle blender also known as a stomacher) doesn't produce a homogeneous mixture. Instead, the desired contents are extracted by pressing a solid sample against a surface with paddles. These are typically living cells, bacteria, or other microorganisms circulating in solution.

Uses

Homogenizers with paddles are made specifically for washing or extracting microorganisms into solutions. They are widely utilized in life science research and food and environmental testing applications. They might also work well in some situations where tissue dissociation is sought.

Benefits

A paddle blender works well in the context of its intended uses.

Drawbacks

- Care must be taken before purchasing because paddle blender bags can be challenging to handle and store.

- Beyond the narrow uses for which it is intended, a paddle blender is of limited use.

Choosing the Correct Homogenizer Manufacturer

To ensure you have the most productive outcome when purchasing homogenizers from a homogenizer manufacturer, it is important to compare several companies using our directory of homogenizer manufacturers. Each homogenizer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each homogenizer manufacturer website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple homogenizer companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services