This motor turns the small blades that blend your ingredients into a delicious smoothie when you turn it on. The high speed spinning motion combined with the chopping ability of the blades allows for fast processing of any foods placed in the blender. This same method is also used on a much larger scale for rotor mixers in a variety of industrial applications. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

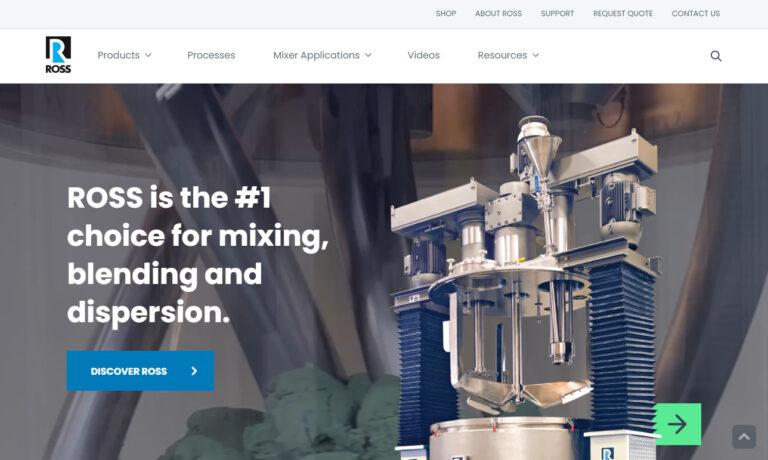

Ross manufactures the world’s broadest line of High Shear Mixers – from traditional High Speed Dispersers and single-stage Rotor/Stator Mixers to new generation ultra- high shear patented mixing technologies. Our high performance rotor/stator mixers are available in sizes from benchtop through full-scale production, in batch and in-line configurations, with a multitude of options to help...

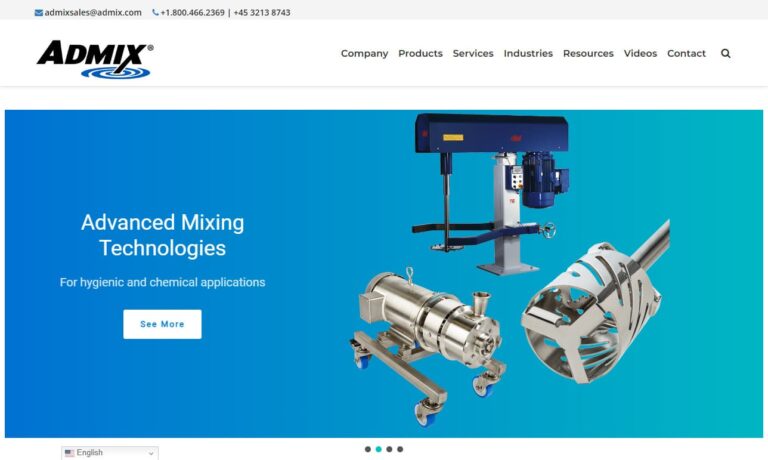

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

For more than 75 years, we have provided custom designed industrial mixing, drying, moving and controlling solutions for the food, plastics, minerals, chemicals, and biomass industries, manufactured to fit the specific requirements of one type of application- yours. It’s simple really, when you’re proud of your work, you sign your name to it. You’ll find it on everything we build. After...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More Rotor Mixer Manufacturers

When a large rotor mixer is used for industrial purposes like chemical mixing or combining food ingredients, a strong electric motor is necessary to create enough power to mix substances of varying densities at high speeds. The rotor is fitted into the bottom of a large stainless steel drum, and it spins at speeds controlled by an exterior control panel.

Sometimes blades or flat mixing arms are the rotating instrument, but many industrial rotor mixers are fitted with what is known as a rotor-stator head. This is a long narrow piece attached to the motor that reaches almost to the top of the container or tank. The rotor-stator has slotted openings that draw materials in and then hurl them outward again, creating a strong centrifugal force. This helps to break materials down to the smallest possible particle size.

Rotor mixers are used in industries like adhesives, chemical processing, food technology and production, pharmaceuticals, ceramics and more. Some rotor mixers are built to operate with different types of attachments, so when the tank is empty a head can easily be detached from the motor and replaced with a more appropriate implement.

This can be very useful in industrial settings where the rotor mixer is needed for multiple types of mixing jobs. For instance, a ribbon blender could be used in place of a rotor-stator to mix powders, pet foods and seasonings. These are dry substances that require the spiral blades of a ribbon blender to move through the circumference of the entire container rather than create the centrifugal force generated by a rotor-stator and most often used in liquid mixtures.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services